Estimated Reading Time: 30-35 minutes (6,147 words)

Introduction

The global automotive industry is undergoing its biggest transformation since the invention of the internal combustion engine. Electric vehicles have gone from niche to mainstream, plug-in hybrids dominate family segments, and battery innovations are accelerating at record speed. Amid this rapid shift, hydrogen cars — once considered a distant, sci-fi concept — are finding their way back into boardrooms, policy discussions, and automaker roadmaps.

What’s driving this resurgence? Governments are pouring billions into green hydrogen infrastructure, global automakers are reviving fuel-cell vehicle (FCV) programs, and countries like India, Japan, South Korea, and Germany are positioning hydrogen as a key pillar of their long-term clean-mobility strategy. With India rolling out hydrogen bus trials, pilot refueling stations, and incentives under the National Green Hydrogen Mission, curiosity around hydrogen-powered mobility is at an all-time high.

This brings us to the critical question at the heart of the debate:

Are hydrogen cars truly the next big frontier in clean mobility… or are they simply another cycle of technological hype that won’t scale?

In this deep-dive, we break down the science, real-world economics, infrastructure gaps, policy frameworks, automaker plans, and global adoption data to evaluate how hydrogen cars stack up against EVs — and whether they realistically have a future, especially in India’s price-sensitive, infrastructure-constrained automotive market.

Consider this your definitive, data-backed guide to the future of hydrogen mobility.

What Are Hydrogen Cars?

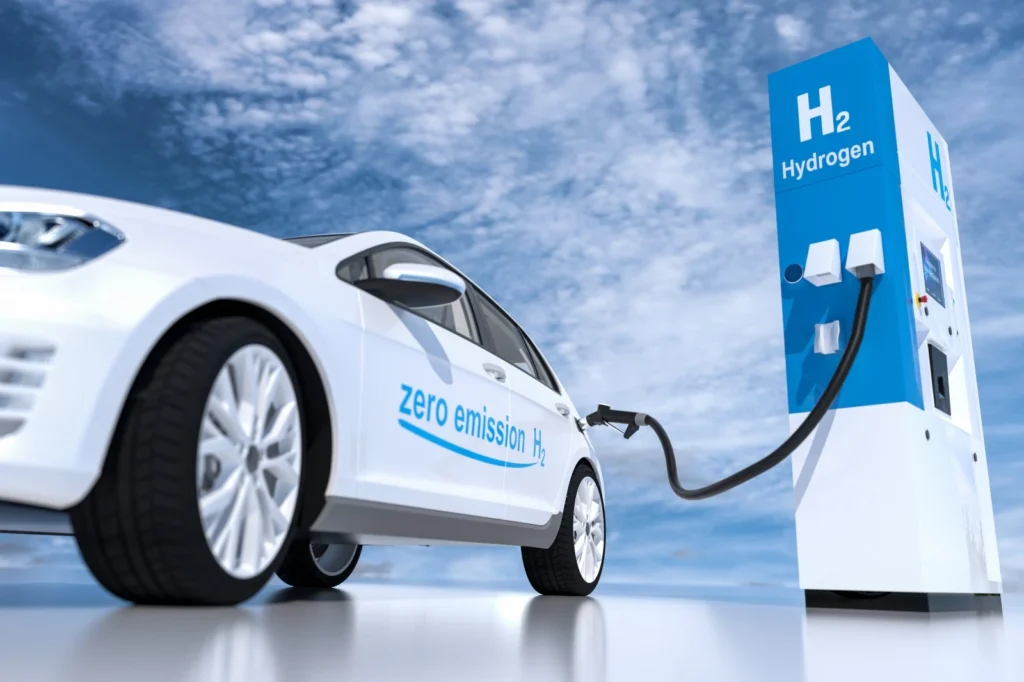

Hydrogen cars — also known as Fuel Cell Electric Vehicles (FCEVs) — are vehicles powered by electricity, but instead of storing energy in large lithium-ion batteries like traditional EVs, they generate their own electricity onboard. They do this using compressed hydrogen gas and a fuel cell stack, where hydrogen reacts with oxygen in the air to produce electricity through an electrochemical process.

This makes hydrogen cars unique:

- They drive like EVs, with instant torque and quiet operation.

- But they refuel like petrol cars, taking just 3–5 minutes at a hydrogen station.

- And they emit zero tailpipe pollution — the only byproduct is water vapor, making them one of the cleanest mobility technologies on paper.

Inside an FCEV, the fuel cell produces continuous electric power, while a small battery stores excess energy generated during braking. This hybrid structure allows hydrogen cars to deliver long range, consistent performance, and suitability for heavier vehicles like buses and trucks.

Common commercially available FCEV models include:

- Toyota Mirai – The world’s most popular hydrogen car, known for its 600+ km range and mature fuel-cell platform.

- Hyundai Nexo – A premium SUV with advanced driver assistance features and one of the longest hydrogen ranges globally.

- Honda Clarity FCEV (limited markets) – Offered primarily in Japan and parts of the U.S., known for its efficiency and smooth drive.

While still niche today, these models represent the forefront of hydrogen mobility, with more automakers now revisiting their FCEV plans as part of long-term decarbonization strategies.

How Hydrogen Fuel Cell Technology Works

Hydrogen fuel cell technology may sound complex, but at its core, it follows a clean and elegant electrochemical process. Instead of burning fuel like traditional engines, hydrogen cars create electricity on demand using a chemical reaction — no combustion, no explosions, just clean power.

Step-by-Step (Simple Explanation)

- Hydrogen is stored in a high-pressure tank

- FCEVs carry hydrogen at 700 bar (10,000 psi) in reinforced carbon-fiber tanks.

- These tanks are extremely safe and designed to withstand accidents, temperature extremes, and punctures.

- FCEVs carry hydrogen at 700 bar (10,000 psi) in reinforced carbon-fiber tanks.

- It enters a fuel cell stack

- The “engine” of a hydrogen car is a fuel cell stack containing hundreds of thin membrane cells.

- Each tiny cell produces a small amount of electricity; combined, they power the entire vehicle.

- The “engine” of a hydrogen car is a fuel cell stack containing hundreds of thin membrane cells.

- Hydrogen reacts with oxygen from the air

- Oxygen is drawn in through the front air intake.

- Inside each cell, hydrogen molecules split into protons and electrons.

- Oxygen is drawn in through the front air intake.

- A chemical reaction generates electricity

- Protons pass through a membrane (PEM: Proton Exchange Membrane).

- Electrons take an external path — creating an electric current.

- This current is what drives the car’s motor.

- Protons pass through a membrane (PEM: Proton Exchange Membrane).

- Electricity powers the motor

- The vehicle uses this electricity to power an electric drivetrain, similar to EVs.

- A small lithium-ion battery buffers excess energy and supports acceleration.

- The vehicle uses this electricity to power an electric drivetrain, similar to EVs.

- Water vapor is released through the exhaust

- After the reaction, hydrogen and oxygen recombine into pure water (H₂O).

- This exits the tailpipe as harmless water vapor, making FCEVs true zero-emission vehicles.

- After the reaction, hydrogen and oxygen recombine into pure water (H₂O).

Why It Matters

- Uses no combustion

There is no burning of fuel — reducing pollution, improving energy efficiency, and eliminating harmful emissions like NOx, PM2.5, or CO₂. - Higher efficiency than gasoline

Hydrogen fuel cells operate at 40–60% efficiency, while traditional petrol engines typically run at only 20–25% efficiency. - Very quiet, EV-like drive quality

Since electricity powers the drivetrain, FCEVs offer silent acceleration, smooth rides, and instant torque — similar to premium EVs. - Full tank refuels in ~3–5 minutes

The biggest advantage over battery EVs:

- No long charging time

- No battery degradation concerns

- Ideal for taxis, buses, logistics fleets, and long-distance travel

- No long charging time

Global Market Overview

(Sources sampled: IEA, H2stations.org, Mordor Intelligence, Reuters/IEA coverage, H2 industry trade press, OEM releases)

Key Stats Box

- Global hydrogen demand: 97–100 million tonnes in 2023–24 (demand still concentrated in refining & chemicals). IEA+1

- Hydrogen refuelling stations: >1,000 stations in operation worldwide by end-2024 (≈125 new stations added in 2024). H2Stations.org+1

- Market-size forecasts (varied): fuel-cell / hydrogen vehicle market estimates range widely — e.g., Mordor: ≈USD 2.9B (2025) → USD ~20B (2030) in one fuel-cell vehicle report; other agencies give higher/lower numbers depending on scope. (See two sample forecasts below). Mordor Intelligence+1

- Geographic hotspots: Japan, South Korea, parts of the EU, California, China (policy support, subsidies, early station networks). IEA+1

What’s Driving Global Interest

- Net-zero & industrial policy commitments — Governments aiming for 2050 net-zero see hydrogen as a low-carbon energy vector for hard-to-electrify sectors (steel, chemicals, heavy transport), which indirectly supports mobility applications via supply scaling and hydrogen hubs. The IEA’s Global Hydrogen Review tracks this policy momentum even as it notes many proposed projects are still early-stage. IEA+1

- Heavy-duty transport needs — Hydrogen’s high gravimetric energy and fast refuelling make it attractive for long-haul trucking, coaches, and shipping—applications where batteries face weight and charging-time limits. That commercial case is the primary near-term growth engine for FCEVs. hydrogeninsight.com+1

- Cost reductions in green hydrogen (potential) — Falling renewables costs and scaling electrolysers could bring down the levelized cost of hydrogen (LCOH). However, the IEA and Reuters recently warned that announced low-emissions hydrogen projects and electrolyser roll-outs have been cut back, slowing the pace of cost reduction unless policy and financing intensify. In short: cost declines are possible but not guaranteed. Reuters+1

- OEM R&D and selective commercialization — Toyota, Hyundai and other OEMs continue to invest in FCEV platforms (Mirai, Nexo and concept programs), and several manufacturers are pairing hydrogen efforts with heavy-duty pilots. But OEM strategies are mixed — some firms are doubling down while others (notably Stellantis in 2025) have pulled back, highlighting industry risk and strategic divergence. Mordor Intelligence+1

Market forecasts & why they diverge

Market-research forecasts for the hydrogen/hydrogen-vehicle market vary widely because each model uses different assumptions about:

- Which vehicle segments are counted (light duty vs heavy duty vs buses/trucks).

- Speed of green H₂ cost declines (electrolyser CAPEX and renewable electricity prices).

- Scale and pace of station rollouts and supporting subsidies.

For example, Mordor and some fuel-cell market reports show high CAGRs and multi-billion-dollar markets by 2030, while the IEA has recently reduced its 2030 low-emissions hydrogen production outlook, citing project cancellations and financing issues. These conflicting signals mean market numbers should be treated as scenario ranges rather than a single forecast. Mordor Intelligence+1

Regional breakdown & infrastructure momentum

- Japan & South Korea: Strong national programmes (subsidies, public fleets, station rollouts) and corporate alignment (automakers + utilities). These countries remain global leaders in passenger and bus FCEV pilots. IEA

- Europe: A mixture of heavy-duty pilots and truck corridors, plus EU electrolyser targets that could create local green H₂ supply — though corporate reorganizations (like Stellantis’ pullback) show fragility in private investments. Le Monde.fr+1

- China: Rapid, state-backed deployment in commercial vehicles and refuelling infrastructure; China is also becoming dominant in electrolyser manufacturing. hydrogeninsight.com+1

- California & North America: Policy and early incentive programs have created local demand, but station reliability and funding remain recurring issues that have pressured retail FCEV adoption in some pockets. Driving Hydrogen+1

On infrastructure: while the global count passed the 1,000-station milestone in 2024, stations remain highly concentrated and far fewer than EV chargers—meaning geographic coverage is still the gating factor for passenger FCEV scale. H2Stations.org+1

What the data says about volumes (reality check)

- Passenger FCEV sales remain tiny: multiple industry trackers reported notable declines in hydrogen-car sales through early- to mid-2025 (some analyses show a ~27% drop in H1 2025), with OEMs like Toyota and regional outages in station networks cited as causes. That underscores the fragile, pilot-scale nature of current FCEV retail markets. hydrogeninsight.com+1

- Fleet & commercial uptake is more promising: bus and truck pilots, plus captive industrial fleets, show stronger, more stable commercial cases — tighter duty cycles and centralized refuelling make economics and operations simpler to manage. hydrogeninsight.com+1

Bottom line — “But Volume Is Still Low”

Despite strong policy statements and eye-catching forecasts, hydrogen passenger cars remain a niche for several reasons:

- Sales share is tiny vs global auto volumes, and several 2025 data points show declining retail FCEV sales in many markets. hydrogeninsight.com+1

- Refuelling networks are sparse (1,000+ stations is a milestone, but the distribution is limited and maintenance/reliability issues have constrained consumer confidence). H2Stations.org+1

- Per-vehicle and fuel costs are still higher than BEV equivalents on many total-cost-of-ownership comparisons, especially where electricity for BEVs is cheap and fast-charging networks are expanding rapidly. Reuters+1

These facts support the current consensus among many analysts: hydrogen mobility is far from dead, but it is specialized — poised to grow fastest where its technical strengths solve real operational pain points (heavy-duty, long-range, high-utilization fleets) rather than displacing mass consumer BEVs.

India’s Hydrogen Car Roadmap

India is positioning itself as a major green hydrogen superpower, aiming to cut oil imports, reduce industrial emissions, and build a future-ready clean mobility ecosystem. While hydrogen passenger cars are still at a pilot stage, India’s strategy is built around scaling infrastructure, production, and heavy-duty applications first — where hydrogen’s real strengths lie.

Key Government Initiatives

National Green Hydrogen Mission (NGHM) – ₹19,744 crore commitment

Launched in 2023, the NGHM aims to make India a global hub for green hydrogen production, use, and export.

Targets include:

- 5 MTPA of green hydrogen production by 2030

- 125 GW of renewable energy capacity addition dedicated to hydrogen

- Incentives for electrolyser manufacturing and hydrogen hubs

This mission underpins all hydrogen mobility pilots across states.

Green Hydrogen Policy (2022)

The policy introduced major incentives to accelerate hydrogen projects:

- No inter-state transmission charges for 25 years

- Banking of renewable energy for 30 days

- Faster land allocation in RE parks

- Priority grid connectivity

These benefits lower the cost of green hydrogen production — a critical factor for FCEV feasibility.

Pilot corridors for hydrogen buses and trucks

The government and PSU partners are building hydrogen mobility corridors on high-volume freight routes such as:

- Delhi–Jaipur

- Mumbai–Pune

- Delhi–Agra

- Ahmedabad–Vadodara

These corridors will host refuelling stations, hydrogen hubs, and dedicated trials for heavy-duty commercial vehicles.

NTPC, IOCL, HPCL, and private players testing fuel cell vehicles

Several entities are already running hydrogen mobility pilots:

- NTPC: Hydrogen buses in Leh & Delhi

- IOCL: Fuel cell truck pilots with Tata Motors; also developing hydrogen-diesel dual-fuel engines

- Maruti/Suzuki, Tata Motors, Ashok Leyland: Fuel cell R&D and prototypes

- Reliance & Adani: Announced plans to enter green hydrogen production at scale

These trials play a crucial role in validating performance in Indian conditions (heat, dust, monsoons).

India’s first hydrogen refuelling stations under development

Hydrogen stations are being set up or planned in:

- Delhi (IOCL R&D Centre, Dwarka)

- Gujarat (Hazira, Dahej, Kandla Port region)

- Maharashtra (Mumbai–Pune Expressway, Navi Mumbai)

- Ladakh (Leh hydrogen mobility project)

- Upcoming sites in Bengaluru, Hyderabad, and Chennai hydrogen clusters

India is also exploring mobile refuelling units to reduce early-stage infrastructure costs.

India’s Biggest Advantages

1. One of the world’s lowest renewable energy costs

India’s solar prices have fallen to ₹1.99–2.50 per kWh, making green hydrogen production potentially cheaper than global averages. Low energy input = competitive hydrogen.

2. Ability to produce low-cost green hydrogen

With scaling electrolysers, India aims to produce green hydrogen at $1–2/kg by 2030, compared to $4–6/kg today globally. This could make India a major exporter to Europe and Asia.

3. Strong industrial clusters (refining, steel, chemicals)

Industries like:

- Reliance (Jamnagar)

- Tata Steel (Jamshedpur)

- JSW Steel (Vijayanagar)

- Indian Oil refineries

are already exploring H₂ for decarbonization — making hydrogen supply chains more viable for mobility.

4. High-pollution cities → need clean mobility

Cities like Delhi, Gurugram, Ghaziabad, Bengaluru, and Mumbai face severe PM2.5 levels.

Hydrogen buses and logistics fleets can cut heavy-duty pollution, which contributes significantly to urban emissions.

Where Hydrogen Fits in India

While battery EVs dominate passenger adoption, hydrogen has a clear market fit in sectors where EVs face real-world limitations:

Hydrogen is most viable for:

✔ Intercity buses

- Long distances (300–800 km/day)

- Minimal downtime

- Existing depot-based refuelling makes H₂ logistics easier

✔ Long-haul trucking

Hydrogen trucks can offer:

- Faster refuelling

- Lower payload loss vs heavy batteries

- Potential for 800–1,000 km range

✔ Ports & logistics hubs

India’s major ports (JNPT, Mundra, Kandla) are piloting hydrogen trucks, forklifts, and yard vehicles.

✔ Industrial fleet vehicles

Refineries, steel plants, and mining operations can operate captive H₂ fleets with onsite production.

✔ High-utilization commercial transport

Fleets that run 24×7 (airport shuttles, couriers, intercity cabs) benefit from quick refuelling + long range.

Passenger hydrogen cars will remain niche for now.

India still lacks:

- A hydrogen refuelling network

- Consumer incentives

- Affordable H₂ supply

- Proven retail demand

Therefore, FCEV passenger cars (like Mirai/Nexo) will remain extremely limited until 2030 or beyond.

The real action in India’s hydrogen mobility sector is in commercial and industrial fleet applications.

Hydrogen Cars vs Electric Cars

Below is a detailed side-by-side comparison that highlights the real-world strengths, limitations, costs, infrastructure gaps, and ideal use-cases of both technologies.

Hydrogen Cars (FCEVs) vs Battery EVs (BEVs)

| Feature | Hydrogen Cars (FCEVs) | Battery EVs (BEVs) |

| Refuelling / Charging Time | 3–5 minutes for a full tank (similar to petrol/diesel) | 30–60 minutes with DC fast charging; 6–12 hrs on home AC |

| Driving Range | Generally 600–700 km per tank; consistent performance in cold/heat | 350–500 km average; varies by model & temperature |

| Energy Efficiency | Lower well-to-wheel efficiency (approx. 25–35%) due to conversion losses | Higher efficiency (70–90% depending on drivetrain) |

| Fuel / Energy Cost | Hydrogen costs are higher and vary widely; green H₂ still expensive | EV charging is cheaper per km, especially home charging |

| Zero Emissions | Yes — only water vapor from tailpipe | Yes — no tailpipe emissions |

| Infrastructure Availability | Very limited globally; early-stage in India | Rapidly expanding public + home charging |

| Vehicle Purchase Cost | Typically higher due to fuel-cell stack & hydrogen tanks | More affordable with falling battery prices |

| Maintenance | Lower than ICE; fuel-cell stack lasts 5,000–8,000 hours | Low; fewer moving parts, battery warranty 6–8 years |

| Fuel Storage | Hydrogen stored at 700 bar pressure; requires specialized tanks | Electricity stored in lithium-ion batteries |

| Driving Experience | Smooth, quiet, instant torque (same as EVs) | Smooth, quiet, instant torque (same as FCEVs) |

| Environmental Impact (Production) | Green hydrogen production still limited; grey hydrogen emits CO₂ | Battery production emits CO₂ but improving via recycling |

| Safety Considerations | Hydrogen tanks extremely strong but require strict handling | Battery fires rare but difficult to extinguish |

| Best Use Cases | Long-range travel, heavy-duty transport, fleets, high-utilization mobility | Urban commuting, personal cars, taxis, city logistics |

| Global Market Adoption | Very small market (<0.1% of auto sales) | Rapid adoption; millions of sales per year |

| India-Specific Feasibility | Better for buses, trucks, industrial fleets | Best option for personal mobility and mass adoption |

Winner (Mass Market): Battery EVs

BEVs win for the general population, daily city use, affordability, and infrastructure availability.

India’s EV ecosystem (charging, battery manufacturing, subsidies) is growing at scale, making BEVs the clear mainstream option through 2030.

Winner (Heavy Duty & Long Range): Hydrogen

Hydrogen excels where BEVs struggle:

- Long-haul trucks

- Intercity buses

- Ports, mining, airports

- High-utilization commercial fleets

- Industrial clusters

Its fast refuelling + long range gives FCEVs an operational advantage for commercial applications.

TCO (Total Cost of Ownership) Comparison: Hydrogen Cars vs Battery EVs in India

When evaluating future mobility for India, upfront cost alone isn’t enough — what matters is lifetime cost, which includes purchase price, energy/fuel expense, maintenance, subsidies, battery/fuel-cell durability, resale value, and infrastructure availability. Here’s a detailed breakdown:

1. Purchase Price

Hydrogen Cars

- Expected to be significantly more expensive (₹45–60 lakh+ for first-gen models like Toyota Mirai or Hyundai Nexo).

- Fuel cell stacks, high-pressure tanks, and low production scale increase cost.

- Zero localized manufacturing in India → heavy import duties.

Battery EVs

- Much more affordable (₹10–50 lakh across Tata, MG, BYD, Kia, Hyundai).

- Local battery assembly + lower taxes under FAME / state EV policies.

- Economies of scale improving rapidly with new gigafactories.

TCO Impact: EVs win due to far lower upfront cost.

2. Fuel / Energy Cost (Per 1,000 km)

Hydrogen Cars

- India has almost no commercial hydrogen pumps, so real cost is theoretical.

- Green hydrogen expected at ₹250–350/kg initially; cars use 1kg for 100 km.

- Per 1,000 km ≈ ₹2,500–3,500 (may drop in future but still high today).

Battery EVs

- Home charging at ₹8–10/unit.

- Most EVs consume 13–16 kWh per 100 km.

- Per 1,000 km ≈ ₹1,200–1,600.

- Even public fast charging is cheaper than hydrogen fuel.

TCO Impact: EVs cost ~50% less to “fuel.”

3. Maintenance & Servicing

Hydrogen Cars

- Fewer moving parts than ICE, but:

- Expensive fuel cell stack replacements

- High-pressure hydrogen tank inspections

- Limited service network

- Expensive fuel cell stack replacements

- Annual service cost likely higher until local industry matures.

Battery EVs

- Lowest maintenance among all vehicle types.

- No oil, no exhaust, no engine cooling fluids (mostly).

- Battery degradation manageable with warranties.

TCO Impact: EVs clearly cheaper to maintain.

4. Infrastructure Availability

Hydrogen Cars

- Almost nonexistent retail hydrogen stations in India.

- Fleet-only pilots (buses, trucks) running on government-backed hydrogen hubs.

- Public adoption impossible without billions in station investments.

Battery EVs

- Fastest-growing infrastructure in India:

- Home + workplace charging

- Public DC fast chargers expanding across highways

- Heavy corporate + DISCOM investments

- Home + workplace charging

TCO Impact: EV infrastructure is usable today — hydrogen is not.

5. Resale Value

Hydrogen Cars

- Uncertain due to:

- No ecosystem

- High component cost

- Niche buyer base

- No ecosystem

Battery EVs

- Improving resale value as demand grows.

- Battery warranties (8 years+) give buyer confidence.

TCO Impact: EVs likely to retain better value short-term.

6. Lifetime Cost Projection (5 Years / 75,000 km)

Hydrogen Car (Estimated)

- Purchase: ₹50 lakh

- Fuel: ~₹2.2 lakh

- Maintenance: ~₹1.5 lakh

- Total (5 years): ₹53.7 lakh

Battery EV

- Purchase: ₹20–40 lakh (mid: ₹30 lakh)

- Electricity: ~₹1.1 lakh

- Maintenance: ~₹0.7 lakh

- Total (5 years): ₹31.8 lakh

TCO Impact: Battery EVs are nearly 40–50% cheaper over 5 years.

Final Verdict (India-Specific)

Hydrogen Cars — Best for…

- Long-haul commercial fleets (buses, trucks)

- Industrial corridors with hydrogen hubs

- High-utilization vehicles needing fast refueling

Battery EVs — Best for…

- Mass-market adoption

- Personal mobility

- City + highway travel

- Affordable TCO and quick scaling

Winner (India 2025–2035): Battery EVs

Hydrogen may rise later for heavy mobility, but for Indian consumers and most passenger vehicles, EVs dominate TCO by a wide margin.

Key Benefits of Hydrogen Cars

✔ Ultra-Fast Refuelling (3–5 Minutes)

Hydrogen cars offer one of the biggest advantages over battery EVs — refueling speed. A hydrogen tank can be filled in just 3–5 minutes, almost identical to petrol or diesel.

This makes fuel-cell vehicles ideal for:

- Fleet vehicles that cannot afford long charging downtime

- Highway travel

- Commercial vehicles and taxis that run multiple shifts a day

- Long-haul trips where fast turnaround is essential

Unlike EV charging, refuelling time stays constant regardless of tank size or temperature.

✔ Long Range (Up to 700 km+)

Hydrogen cars typically deliver 600–700 km on a single tank, with models like the Toyota Mirai and Hyundai Nexo regularly achieving these numbers in real-world driving.

Why this matters:

- More predictable long-distance travel

- Less dependence on charging networks

- Suitable for intercity routes and logistics

- Lower “range anxiety” even compared to many premium EVs

The high range comes from hydrogen’s superior energy density — it stores more energy per kg than lithium-ion batteries.

✔ Lightweight Energy Storage

Hydrogen provides long range without adding excessive weight, a key reason why many experts say fuel cells make more sense for heavy vehicles.

In large trucks, buses, and cargo vehicles:

- Battery packs can weigh over 1–2 tons

- Added weight reduces payload

- Vehicles become more expensive and slower

Fuel cell systems, on the other hand:

- Are much lighter

- Provide consistent power for extended distances

- Enable higher payload capacity

This is why hydrogen is rapidly scaling in commercial transport, even where passenger adoption is slow.

✔ Ideal for Extreme Cold Climates

Hydrogen fuel cells perform reliably in low temperatures, unlike lithium batteries which lose significant range in cold weather (sometimes up to 30–40%).

Benefits in winter conditions:

- Minimal loss of range

- No slow charging issues

- No need for battery preconditioning

- Smoother power delivery in sub-zero temperatures

This makes hydrogen popular in regions like Japan, South Korea, Canada, and Northern Europe, where cold weather challenges battery efficiency.

Why Hydrogen Cars Are Still Not Mainstream

Despite their impressive potential, hydrogen cars remain a tiny fraction of global vehicle sales. Several structural, economic, and technological barriers prevent them from scaling like battery EVs. Here’s a deep dive into the key reasons:

1. Extremely Limited Refuelling Infrastructure

Hydrogen stations are still rare and expensive to build.

- Only 1,000+ stations exist worldwide, mostly concentrated in Japan, South Korea, Germany, and California.

- India currently has only pilot stations, not commercial ones.

- A single hydrogen refuelling station costs ₹20–30 crore depending on capacity and technology.

This makes long-distance planning difficult and discourages both consumers and automakers.

2. High Production Costs for Green Hydrogen

Green hydrogen — the cleanest form — is still expensive to produce due to:

- High electrolyser costs

- Energy-intensive production

- Limited renewable energy integration in most countries

Today, green hydrogen costs around $3–6 per kg globally, and India aims to reduce it to $1–2 per kg by 2030, but that target is still years away.

3. Hydrogen Cars Are Significantly More Expensive

Fuel-cell vehicles (FCEVs) cost more due to:

- Costly platinum-based catalysts

- Complex high-pressure tanks

- Limited economies of scale

- Low global production volumes

Hydrogen cars like the Toyota Mirai and Hyundai Nexo are priced well above ₹50–60 lakh in global markets — much higher than similarly ranged EVs.

4. Efficiency Losses Across the Hydrogen Value Chain

Hydrogen involves multiple conversion stages:

Electricity → Hydrogen → Compression/Liquefaction → Transport → Fuel Cell → Electricity

Each step loses energy, resulting in:

- Overall efficiency of 25–35% for hydrogen cars

- Compared to 70–90% efficiency for battery EVs

This makes hydrogen less energy-efficient for personal vehicles.

5. Storage & Transportation Challenges

Hydrogen is difficult to handle because it is:

- Highly flammable

- The smallest molecule (causes leakage)

- Stored at very high pressure (350–700 bar)

- Sensitive to temperature and material fatigue

Transporting hydrogen via pipelines or trucks adds further cost and logistical complexity.

6. Automakers Are Prioritizing Battery EVs

Most major automakers (Tesla, VW, Tata, Mahindra, BYD, Mercedes, Ford) have shifted resources heavily toward EVs.

Reasons:

- Larger customer base

- Faster charging network expansion

- Stronger government subsidies for EVs

- Simpler manufacturing supply chains

- Falling battery prices

Only a few automakers — Toyota, Hyundai, Honda, BMW — continue to invest in hydrogen passenger cars.

7. Lack of Consumer Awareness & Confidence

Hydrogen is still misunderstood by most buyers.

Top concerns:

- “Is it explosive?”

- “Where will I refuel?”

- “Will the tech survive long-term?”

- “Is hydrogen safe inside my car?”

- “Why should I buy hydrogen instead of EV?”

Without mass-market education, demand remains low.

8. Better Fit for Heavy-Duty Transport Than Personal Cars

Most experts now agree:

Hydrogen makes more economic sense for heavy-duty, long-range, commercial applications — not for everyday passenger cars.

This natural market shift reduces investment in hydrogen sedans and SUVs.

Bottom Line

Hydrogen cars are technologically impressive but face serious real-world challenges. High costs, infrastructure gaps, and stronger EV momentum mean hydrogen passenger cars will likely remain niche for the next decade — while hydrogen’s true disruption potential lies in buses, trucks, industrial fleets, and long-haul mobility.

Major Challenges Blocking Adoption of Hydrogen Cars

Even though hydrogen mobility has strong long-term potential, several structural and economic barriers limit mainstream adoption today. Below is a deeper breakdown of the biggest roadblocks.

1. Infrastructure Is the Biggest Bottleneck

Hydrogen refuelling stations are extremely expensive and technically complex to build.

- A single commercial-grade station costs $2–3 million (₹16–25 crore) depending on capacity, compression technology, and location.

- They require specialized equipment: high-pressure compressors, cooling systems, storage tanks, safety systems, sensors, and regulatory approvals.

- Unlike EV charging stations (which can scale quickly), hydrogen stations need high-grade land, advanced engineering, and trained technicians.

Current reality:

- Only 1,000+ stations exist worldwide (mostly Japan, Korea, Germany).

- India has fewer than 5 pilot stations — none yet accessible to the public.

This infrastructure gap is the single largest barrier to hydrogen car adoption.

2. High Cost of Green Hydrogen

Green hydrogen — produced via electrolysis powered by renewables — is central to hydrogen cars. But it’s still too costly today.

Global price ranges (IEA 2024):

- $4–6 per kg for green hydrogen

- $1–2 per kg for grey hydrogen (made from natural gas, not clean)

For hydrogen cars to be competitive with EVs:

- The price must drop to $1.5–2.5 per kg (India’s target under the National Green Hydrogen Mission).

- Electrolyser costs must fall by 50–70%.

- Renewable energy expansion must accelerate.

Without cheaper hydrogen, fuel-cell vehicles remain economically unviable for the average consumer.

3. Expensive Vehicles (Fuel Cell Cars Cost 2× EVs)

Fuel-cell vehicles (FCEVs) are still low-volume, high-tech, and expensive to produce.

Examples:

- Toyota Mirai: ~$50,000–65,000 globally

- Hyundai Nexo: ~$60,000+

- Honda Clarity FCEV: Limited rollout due to high production cost

Why so expensive?

- Platinum-based catalysts in fuel cells

- Carbon-fiber hydrogen tanks able to handle 700-bar pressure

- Limited production volume → no economies of scale

- Complex safety and cooling systems

Until mass manufacturing ramps up, FCEVs will remain premium-niche products.

4. Public Safety Perception Issues

Hydrogen is scientifically safe when handled with proper engineering, but public perception remains a challenge.

Key concerns among consumers:

- “Is hydrogen explosive?”

- “What if the high-pressure tank ruptures?”

- “Is it safe during accidents?”

Facts:

- Hydrogen tanks are tested for gunshots, extreme heat, 700-bar pressure, collisions, and even deliberate puncture attempts.

- Hydrogen dissipates upward instantly (lighter than air), reducing fire risk.

- FCEVs adhere to stricter safety standards than petrol/diesel cars.

However, perception lags behind engineering reality, and public fear slows adoption.

5. Heavy Competition From EVs

Battery EVs have already crossed the “early adoption” phase and are scaling globally.

Why EVs are winning faster:

- Rapid expansion of charging networks

- Falling lithium-ion battery prices

- Strong government subsidies

- Simpler technology → easier mass production

- More automakers committed to EV-only roadmaps (Tata, Tesla, BYD, VW, Ford, Mercedes)

Hydrogen passenger cars struggle to compete because:

- EVs already have strong market momentum

- EV charging is far cheaper and easier to deploy

- 2W and 3W segments (huge in India) strongly favour EVs, not hydrogen

- EV infrastructure benefits from millions of users, hydrogen does not

This reinforces EVs as the mass-market solution and hydrogen as a niche.

In Summary

Hydrogen cars face massive economic and infrastructure barriers, along with competition from rapidly scaling EVs. These challenges ensure that for the next 5–10 years, hydrogen cars will grow mostly in:

- Heavy-duty transport

- Long-range commercial fleets

- Industrial logistics

- Government pilot programs

…while EVs dominate the passenger car market.

Cost Breakdown

Understanding the economics of hydrogen mobility requires breaking down costs across fuel, vehicle price, and infrastructure. Hydrogen cars are still significantly more expensive than battery EVs — mainly due to fuel production costs and complex refuelling infrastructure.

A. Cost of Fueling (Hydrogen Fuel Cost vs EV Charging Cost)

Hydrogen cars measure efficiency in terms of kg of hydrogen consumed, not kWh, like EVs.

Hydrogen Fuel Consumption

- 1 kg of hydrogen provides ~100–120 km of range depending on model, load, and driving conditions.

- Most fuel-cell cars have tanks holding 5–7 kg of hydrogen.

Total range per fill:

- 600–700 km (Toyota Mirai, Hyundai Nexo)

- Comparable to long-range diesel cars.

Current Hydrogen Fuel Price (Global)

Hydrogen fuel prices vary by country and subsidy support:

| Region | Price Per Kg | Notes |

| California (USA) | $16–$36/kg | Highest due to supply issues |

| Japan | ~$10–$12/kg | Government-supported |

| South Korea | ~$7–$8/kg | Strong hydrogen infrastructure |

| Europe | $11–$15/kg | Varies by station |

| India (Pilot Projects) | ~$8–$12/kg (estimated) | Not commercially available yet |

Average global refuelling cost:

👉 A full 6–7 kg refill typically costs $70–$150 (₹6,000–₹12,000)

👉 But in subsidized markets, pilot programs bring the cost down to $20–$30 per refill

(This is not the true commercial price — only early government-backed rates.)

EV Charging Cost Comparison

- Home charging cost in India: ₹6–₹8 per kWh

- Fast charging: ₹18–₹25 per kWh

- Cost for 500 km in a typical EV: ₹350–₹450

Hydrogen is 5–7× costlier per km compared to EV charging at current prices.

B. Vehicle Cost (Hydrogen Cars vs EVs)

Hydrogen cars are significantly more expensive due to fuel cell stack technology, high-pressure tanks, and low production volume.

Cost Breakdown

| Vehicle Type | Typical Price Range | Why It Costs More |

| Hydrogen Cars (FCEVs) | $50,000–$70,000 (₹45–60 lakh equivalent) | Fuel cell, carbon-fiber tanks, limited production |

| Battery EVs | $30,000–$50,000 | Mass production + falling battery costs |

Hydrogen cars cost ~25–40% more than comparable EVs.

Reasons:

- Fuel cell stacks use platinum-based catalysts

- Hydrogen tanks operate at 700 bar, requiring expensive carbon-composite materials

- FCEVs are produced in thousands, not millions

- R&D + safety testing costs are very high

In India, if launched today, hydrogen sedans would likely cost ₹60–80 lakh, making them inaccessible for mainstream buyers.

C. Infrastructure Cost (Hydrogen vs EV)

This is the largest and most fundamental economic difference.

1. Hydrogen Refuelling Station Cost

Hydrogen stations require:

- High-pressure compression systems

- Storage tanks (350–700 bar)

- Cooling systems

- Special safety systems

- Trained operators

- Land + regulatory approvals

Cost per hydrogen station:

👉 $2 million–$3 million (₹16–25 crore)

Even small-capacity stations cost over $1 million.

2. Fast EV Charger Cost

Installing EV chargers is dramatically cheaper.

Fast EV Charger (DC):

👉 $20,000–$40,000 (₹16–32 lakh) per charger

Includes hardware + installation.

Slow/AC chargers:

👉 Even cheaper: $400–$1,000

Can be installed in homes, malls, offices, apartments.

Comparison:

- A hydrogen station = cost of 100+ DC fast chargers

- EV infrastructure scales rapidly because it uses existing electricity grids

Summary of Cost Breakdown

| Category | Hydrogen Cars | EVs |

| Fuel Cost | High ($10–$15/kg commercially) | Low (₹6–₹25 per kWh) |

| Vehicle Price | 25–40% higher | Getting cheaper |

| Infrastructure Cost | Extremely high ($2–3M per station) | Very low ($20k–40k per fast charger) |

| Running Cost per km | ~₹6–₹10/km | ~₹1–₹2/km |

Bottom Line

Hydrogen cars are currently far more expensive to fuel, purchase, and support compared to EVs.

Until green hydrogen becomes cheaper and infrastructure expands, hydrogen cars will remain commercial, heavy-duty, and industrial rather than mainstream passenger vehicles.

Real-World Case Studies

Case Study 1: Toyota Mirai (Japan & California)

- Over 20,000 units sold globally

- Government-backed refuelling network

- Success limited to regions with subsidies

Case Study 2: Hyundai Nexo (South Korea & EU)

- Strongest adoption in South Korea

- Hydrogen buses deployed in Seoul

- Government invests heavily in hydrogen stations

Case Study 3: Europe

- Germany, Netherlands, UK running hydrogen truck pilots

- EU targeting 45 GW of electrolyser capacity by 2030

Case Study 4: India

- NTPC & IOCL demonstrated hydrogen buses

- Maharashtra launched India’s first hydrogen-powered bus pilot in 2024–25

- Delhi NCR exploring hydrogen taxis (pilot)

2035 Market Outlook (Global + India)

Global Outlook (2035)

- Hydrogen cars: niche (<5% passenger cars)

- Hydrogen trucks & buses: strong growth

- 5,000–10,000 hydrogen stations

- Major markets: Japan, Korea, EU, California, China

India Outlook (2035)

- Hydrogen passenger cars: niche luxury segment

- Hydrogen buses/trucks: meaningful deployment

- Ports & industrial hubs → hydrogen corridors

- Domestic green hydrogen production reduces costs

Verdict:

Hydrogen cars will not replace EVs, but will become a powerful complement for heavy-duty transport.

FAQs Section

1. Are hydrogen cars better than EVs?

Not in every scenario.

Hydrogen cars excel in long-distance driving, cold climates, and heavy-duty commercial transport such as buses, long-haul trucks, and fleet vehicles. They offer 3–5 minute refuelling and 600–700 km range, making them suitable for high-utilization applications.

Battery EVs are better for daily commuting, urban driving, and personal use due to lower running costs, strong charging infrastructure, and rapidly falling battery prices.

Bottom line: EVs win for mass consumers; hydrogen wins where long range and uptime matter.

2. Is hydrogen safe?

Yes — hydrogen cars meet strict global safety standards.

Fuel tanks are built with carbon-fiber composites, designed to withstand:

- 700-bar pressure

- Direct fire exposure

- High-speed collisions

- Bullet impact testing

- Extreme temperature cycles

- Drop and crush tests

In accidents, hydrogen dissipates vertically into the air (being the lightest element), reducing fire risk. Safety data from Toyota and Hyundai show hydrogen FCEVs are as safe as EVs and petrol cars.

3. Will hydrogen cars replace EVs?

No. The two technologies will coexist, not compete directly.

The automotive industry trend is clear:

- EVs will dominate passenger mobility due to affordability and wide infrastructure.

- Hydrogen will dominate heavy-duty and commercial mobility where batteries become too heavy or slow to charge. Think of hydrogen as the “diesel of the clean mobility era” — optimized for long-distance and industrial use, not everyday sedans.

4. Which countries use hydrogen cars today?

Hydrogen cars are currently available (or expanding) in:

- Japan – World’s largest FCEV market, strong government support

- South Korea – Hyundai’s home market with rapid H₂ infrastructure

- USA (California) – ~55 hydrogen stations; home of the Toyota Mirai market

- Germany – Part of EU’s hydrogen corridor

- China – Major investment in fuel-cell trucks and buses

- UAE – Deploying hydrogen taxis and buses under green hydrogen initiatives

These markets invest heavily in hydrogen corridors and heavy-duty vehicles.

5. Does India have hydrogen refuelling stations?

India has pilot-level hydrogen stations, mainly for testing.

Locations include:

- Delhi NCR – NTPC and IOCL pilot projects

- Gujarat – Industrial hydrogen hubs

- Maharashtra – For truck and bus trials in logistics belts

Under the National Green Hydrogen Mission, India plans to build a hydrogen mobility corridor, but public hydrogen stations may still be 3–5 years away.

6. How long does refuelling a hydrogen car take?

A full hydrogen refill takes 3–5 minutes, similar to petrol or diesel.

This makes hydrogen extremely attractive for:

- Intercity buses

- Long-haul trucks

- Commercial fleets

- Emergency vehicles

- Taxis with high daily utilisation

EVs cannot match this level of uptime today.

7. How far can hydrogen cars travel on one tank?

Most modern hydrogen sedans offer:

- 600–700 km on a single fill (Toyota Mirai, Hyundai Nexo)

Some heavy-duty hydrogen trucks under development exceed: - 800–1,000+ km range per tank

This long range is one of hydrogen’s biggest advantages over EVs.

8. Why are hydrogen cars expensive?

Hydrogen cars are expensive mainly due to:

- Fuel cell stacks that require platinum-based catalysts

- 700-bar carbon-fiber tanks — extremely costly to manufacture

- Limited global production (few thousand units per year)

- Specialized components like humidifiers, compressors, and cooling systems

Because EVs are made in the millions, they benefit from economies of scale — hydrogen cars don’t yet.

9. What is green hydrogen?

Green hydrogen is produced by splitting water into hydrogen and oxygen using renewable electricity (solar, wind).

It is the cleanest type of hydrogen, classified as “zero-emission.”

Hydrogen types:

- Green hydrogen – From renewable energy

- Blue hydrogen – From natural gas with carbon capture

- Grey hydrogen – From natural gas without carbon capture India aims to become a global leader in green hydrogen by 2030, producing some of the world’s lowest-cost H₂.

10. When will hydrogen cars become affordable?

Costs may start to fall significantly between 2028–2035, driven by:

- Large-scale hydrogen production

- Cheaper electrolyzers (prices already falling 20–30%)

- Strong government subsidies

- Increased global interest in hydrogen trucks, buses & fleets

- Local manufacturing in India through NGHM

However, personal hydrogen cars may still remain premium in the near future.

Commercial vehicles will become affordable sooner because fleets run high daily mileage, which improves cost efficiency.

Summary

- Hydrogen cars are no longer just futuristic prototypes; they’re commercially viable machines. However, they haven’t gone mainstream because of high fuel costs, expensive vehicles, and limited refueling infrastructure.

- Right now, hydrogen mobility makes the most sense for heavy-duty applications — trucks, buses, long-haul logistics, and industrial fleets where long range, quick refueling, and high payload matter more than upfront cost.

- For everyday consumers, battery EVs will continue to dominate the passenger vehicle segment over the next decade due to cheaper running costs, better charging ecosystems, and rapidly improving battery tech.

- Countries like India have strong hydrogen potential, especially for commercial transport and industrial decarbonisation, but large-scale adoption will depend on building production hubs, pipelines, and refueling networks.

- Ultimately, hydrogen will scale globally only when fuel prices fall, vehicles become cheaper, and infrastructure expands enough to support mass adoption.

Conclusion

Hydrogen cars are not a myth — but they’re also not the one-size-fits-all future of mobility. The technology is real, proven, and powerful, yet its mainstream adoption is slowed by costs, infrastructure gaps, and production challenges. Where hydrogen truly shines is in sectors that demand long range, rapid refueling, and high payload capacity — qualities crucial for commercial fleets, long-haul trucks, buses, and industrial logistics. In markets like India, the potential is even greater as green hydrogen production becomes more viable through solar, wind, and strategic government push.

EVs, meanwhile, will continue to dominate personal mobility thanks to falling battery prices, expanding charging networks, and strong automaker investment. For everyday consumers, the convenience and economics of EVs make them the more practical choice.

Ultimately, hydrogen and EVs won’t compete as much as they will coexist — each serving different mobility needs. The next decade will determine how quickly hydrogen scales, how affordable it becomes, and how strongly it integrates into the global transport ecosystem.

References & Sources

(Primary reputable sources used while preparing the research section)

- International Energy Agency (IEA) – Global Hydrogen Review

- H2Stations.org – Hydrogen stations data

- Toyota & Hyundai official pressrooms

- BloombergNEF EV & hydrogen outlook

- MarketsandMarkets & Mordor Intelligence hydrogen market reports

- NITI Aayog – Green Hydrogen Roadmap

- NTPC & IOCL pilot project announcements